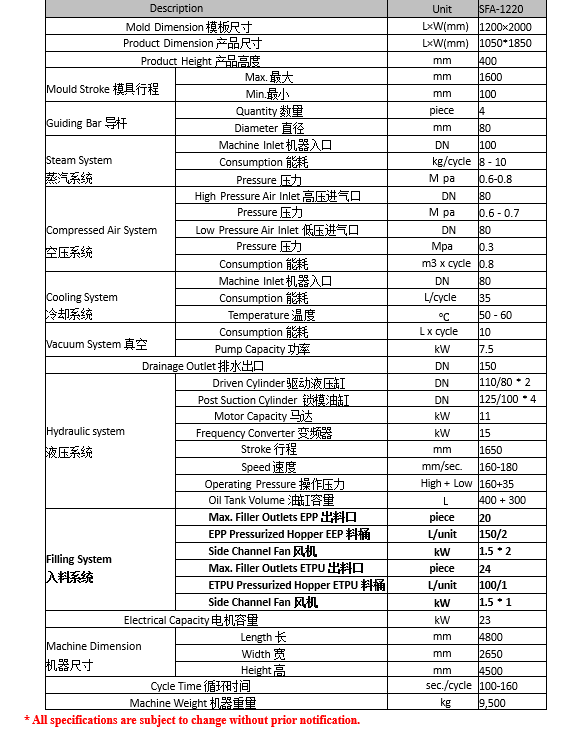

Automatic Multi Function EPP/ ETPU Moulding Machine SFA-1220

Automatic Multi Function EPP/ ETPU Moulding Machine SFA-1220

Press Frames Dimension: 1200 x 2000 mm

Stroke of Machine: 2000 mm

Operating Pressure (Max.): 5 bar

Machine Frame and Construction

Material: The frame is constructed using dimensional steel profiles

and welded with international square tubes. It undergoes CNC machining

and hot zinc galvanization for excellent anti-corrosion properties.

Guiding Bars: Coated with hard chrome for enhanced durability.

Control System

PLC Control Unit: Self-developed programmable logic controller with

USB update functionality and energy-saving solenoid valves for stable and fast response.

Touch Screen: 15.6-inch touch screen control interface

with remote monitoring and data collection capabilities.

CE Compliance: All electrical components comply with CE standards.

Steam System

Double Steam Valves: Main and auxiliary steam valves for faster

and better fusion quality, especially for thick products.

Precision Sensors: Four sets of sensors control steam pressurein the upper

and lower steam chambers for optimal fusion, particularly in multi-cavity, high-density products.

Safety Valves: Equipped with Yoshitake steam pressure reducing valves

and automatic shut-off valves to ensure safety (Industrial 4.0 standard).

Hydraulic System

Frequency Converter: Achieves faster driving and locking motions

with low energy consumption.

Locking Force: Two driven cylinders provide 22.8T locking force,

and four post-suction cylinders provide 15.9T each.

Material Filling System

EPP Filling System: 2 x 150-liter vertical pressurized filling tanks

with pressure sensors and 20 outlets, each equipped with an independent fan.

ETPU Filling System: 1 x 100-liter specially designed pressurized

filling tank with 24 outlets and an automatic blow-back material collection system.

Light Sensors: Equipped with minimum and maximum light sensors for color materials, especially black.

Independent Pressure Control: Each of the 3 tanks has independent pressure control.

Cooling System

Water Vaporization Cooling System: Newly developed system for minimal cooling time,

large coverage area, and high-temperature demolding, with reduced water consumption.

Vacuum System with Condensation Unit: Ensures stable water cooling for

ETPU materials and prevents vacuum system failure due to water suction.